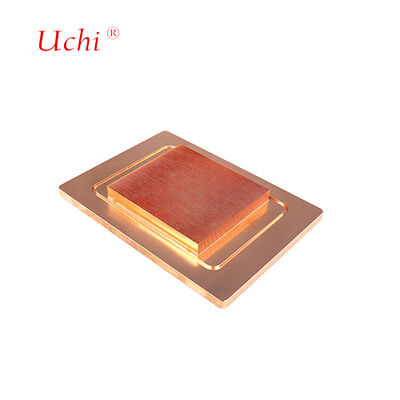

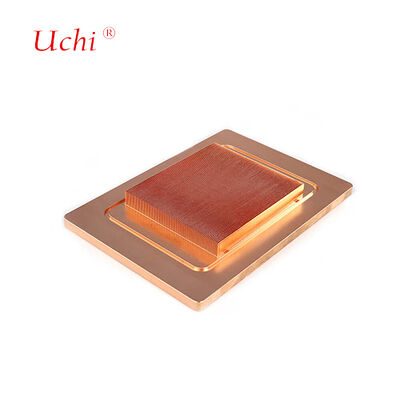

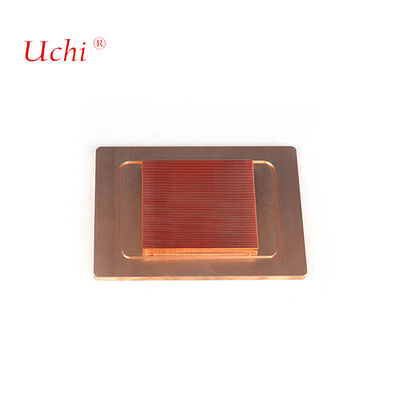

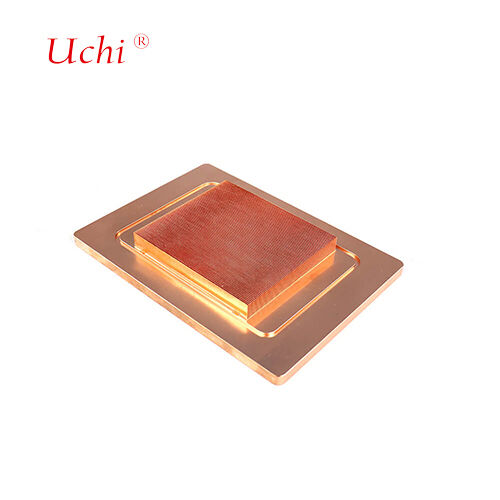

سیستم خنک کننده مایع حرارتی فلک تراکم بالای مس

جزئیات محصول:

| Place of Origin: | Dongguan,Guangdong,China |

| نام تجاری: | Uchi |

| گواهی: | SMC |

| Model Number: | Aluminum Heat Sink |

پرداخت:

| Minimum Order Quantity: | 100pcs |

|---|---|

| قیمت: | قابل مذاکره |

| Payment Terms: | T/T,paypal, Western Union,MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

اطلاعات تکمیلی |

|||

| قدرت هدایت حرارتی: | 30 وات | زندگی هواداران: | 50000 ساعت |

|---|---|---|---|

| مواد: | مس 1020 | اندازه: | 70x70x9mm |

| وزن: | 0.089 کیلوگرم | گواهی: | ISO9001:2015 ISO9001:14001 |

| درمان سطحی: | غیرفعال سازی رسانای گرما | ویژگی: | عملکرد قابل اعتماد و بادوام در مواد |

| برجسته کردن: | سیستم خنک کننده مایع مس,هیت سینک باله ای با چگالی بالا,صفحه خنک کننده مایع با گارانتی,high-density fin heat sink,liquid cooling plate with warranty |

||

توضیحات محصول

تکنولوژی باله های اسکایینگ شامل ماشینکاری دقیق دندان های مس برای ایجاد پروفایل های رادیاتور تخصصی با استفاده از ماشین آلات باله های اسکایینگ پیشرفته است.در نتیجه، بخارگر باله های اسکویینگ دارای یک ساختار شکاف یکنواخت است که توسط برش مکانیکی در زاویه های خاص تشکیل شده است.، به طور خاص برای خنک کردن دستگاه های با قدرت بالا در شرایط خنک کننده هوا طراحی شده است.

این تکنولوژی پیشرفته، در مقایسه با بخاری های سنتی، 8 تا 15 درصد کارایی بیشتری در از بین بردن گرما را ارائه می دهد.تکنولوژی رادیاتور باله های اسکویینگ ما به طور قابل توجهی رشد کرده است، با بهبود سطح اتوماسیون و مزایای قابل توجهی در هزینه و قابلیت اطمینان.

- سیستم های UPS

- تجهیزات ایستگاه پایه

- زیرساخت های انبار شارژ

- تبدیل کننده های فرکانس

- کنترل کننده های صنعتی

- مبدل های انرژی بادی

- سیستم های SVG

- راه حل های روشنایی LED

چراغ های خیابانی LED با قدرت بالا، چراغ های کارخانه، چراغ های صحنه و چراغ های رشد گیاهان.افزایش عمر لامپ و حفظ بهره وری نور پایدار.

کاربردهای دارای تراکم قدرت بالا از جمله منابع برق سرورها، ماژول های برق ارتباطی، سیستم های UPS، تبدیل کننده های فرکانس صنعتی، ایستگاه های شارژ خودروهای الکتریکی،و اینورترهای خورشیدیبخاری های گرما اکستروژ شده تضمین می کنند که دستگاه های نیمه هادی قدرت در محدوده های دمای ایمن کار می کنند و از گرم شدن بیش از حد و شکست جلوگیری می کنند.

کامپیوترهای صنعتی، کنترل کننده های منطقی قابل برنامه ریزی (PLCs) ، درایوهای سرو و کنترل کننده های روبات.بخاری های گرما اکستروژ شده از انتشار گرما برای قطعات الکترونیکی حساس اطمینان حاصل می کنند.، تضمین عملکرد پایدار تجهیزات در دراز مدت.

ایستگاه های پایه 5G، روترها، سوئیچ های شبکه و سرورهای مرکز داده. با افزایش سرعت انتقال داده ها، سینک های گرما اکستروژن شده راه حل های خنک کننده منفعل کارآمد را برای کاهش هزینه های عملیاتی فراهم می کنند.

خنک کننده پردازنده/گروه پردازنده دسکتاپ با عملکرد بالا، کنسول های بازی، سیستم های سینمای خانگی و تلویزیون های صفحه بزرگ.بخاری های خیس شده سفارشی، کارایی تبعید گرما را بهینه می کنند و تجربه کاربر را در طرح های جمع و جور بهبود می بخشند.

سیستم های مدیریت باتری قدرت (BMS) ، کنترل کننده های موتور و شارژر های داخلی.بخاری های گرما اکستروژ شده اجزای حیاتی هستند که عملکرد پایدار سیستم های قدرت را در شرایط مختلف رانندگی تضمین می کنند.

مجموعه تجهیزات خنک کننده هوا ما شامل: 10 کوره بازپرداخت دمای پایین، 5 کوره پخت و پز، 20 واحد توزیع خودکار جوش، 3 سیستم برش خودکار جوش،50 پیچک برقی با کنترل گشتاور، 1 سیستم بازرسی CCD، 2 واحد آزمایش ماژول نوری کاملا خودکار، 11 سیستم آزمایش عملکرد حرارتی چند ایستگاه، 4 واحد آزمایش نوری مسطح و تجهیزات مختلف پشتیبانی.

ما استاندارد های کیفیت سختگیرانه ای را با تجهیزات تست پیشرفته حفظ می کنیم از جمله: 1 دستگاه اندازه گیری مختصات، 1 ابزار پروژکتور، 2 دستگاه آزمایش فشار بالا آب،4 دستگاه آزمایش مقاومت حرارتی، و 2 دستگاه آزمایش نشت مایع.

- پاسخ سریع به تمام سوالات

- قیمت رقابتی با کیفیت تضمین شده

- برنامه ریزی تولید کارآمد

- راه حل های حمل و نقل بهینه

- پشتیبانی فنی جامع