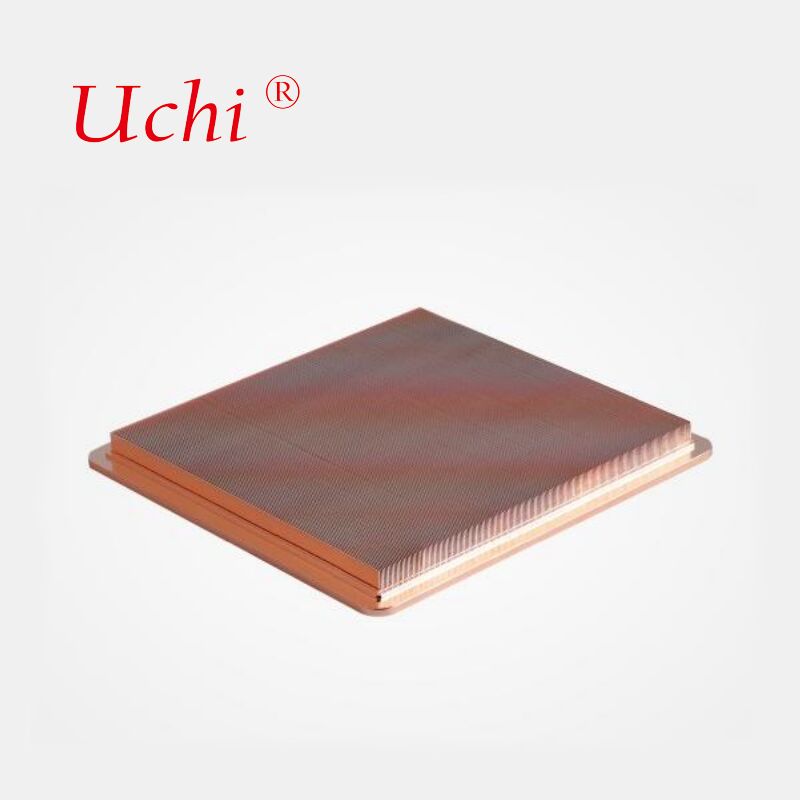

صفحه خنک مایع مربع مینی فن، سرد کننده مس صفحه حرارتی سینک

جزئیات محصول:

| محل منبع: | Dongguan , Guangdong ، چین |

| نام تجاری: | Uchi |

| گواهی: | SMC |

| شماره مدل: | هیت سینک باله دار 03 |

پرداخت:

| مقدار حداقل تعداد سفارش: | 100 عدد |

|---|---|

| قیمت: | قابل مذاکره |

| شرایط پرداخت: | T/T، پی پال، وسترن یونیون، مانی گرام |

| قابلیت ارائه: | 50000000 قطعه در هر ماه |

|

اطلاعات تکمیلی |

|||

| خدمات پردازش: | برش، مشت زدن، روکش کردن، خم کردن، سوراخ کردن | خلق و خوی: | T3 ~ T8 |

|---|---|---|---|

| بسته بندی: | کارتن PE BAG | تحمل: | ± 1٪ |

| استاندارد: | هیت سینک آلومینیومی متوسط و با کیفیت | روند کار: | ماشینکاری Cnc |

| مواد: | مس ، آلومینیوم | تکنولوژی: | CNC و اسکی |

| ضخامت: | 0.5-2.5 میلی متر | برنامه: | زمینه ماشین و خودرو |

| برجسته کردن: | صفحه خنک کننده مایع مس,صفحه ی سرد کوچک,خنک کننده ی حرارتی,mini-fin cold plate,square heat sink cooler |

||

توضیحات محصول

صفحه خنک کننده مایع مینی مربع

سینک حرارتی صفحه خنک کننده مسی با عملکرد بالا که برای مدیریت حرارتی کارآمد در کاربردهای پر تقاضا طراحی شده است.

مشخصات محصول

| نام محصول | هیت سینک های سفارشی |

| مواد رایج | مس، آلومینیوم، فلزات دیگر |

| نوع محصول | رادیاتور لوله مسی، رادیاتور ماژول، هیت سینک، محفظه بخار، صفحه خنک کننده مایع، هیت سینک پره زیپی |

| کاربردها | رادیاتورهای خودرو، خنک کننده سرور/مرکز داده هوش مصنوعی، لوازم الکترونیکی مصرفی، ماشین آلات صنعتی، تجهیزات پزشکی، لوازم خانگی |

تخصص شرکت

بیش از 10 سالتجربه در سیستم های حرارتی

بیش از 50 اختراعثبت شده در فناوری حرارتی

بیش از 15 مهندس تحقیق و توسعهمتعهد به نوآوری

5 دکترایدر علوم حرارتی

قابلیت های خدمات

ارائه خدمات کامل از جمله طراحی نقشه های سه بعدی، توسعه قالب، تولید، ماشینکاری، پرداخت سطح و خدمات مونتاژ.

مزایای نرم افزاری و فنی

- قابلیت طراحی پیشرفته سه بعدی Pro/E

- تجزیه و تحلیل شبیه سازی مدیریت حرارتی CFD

- کنترل برنامه CNC دقیق

استانداردهای کیفیت

IATF 16949:2016, GB/T19001-2016/ISO9001:2015, GB/T24001-2016/ISO14001:2015

فرآیندهای ماشینکاری

برش، پانچ، سوراخ کاری، خم شدن، جوشکاری، فرزکاری، ماشینکاری CNC و موارد دیگر

فناوری خنک کننده طبیعی

خنک کننده طبیعی از مواد با هدایت حرارتی بالا برای انتقال گرما و دفع آن به هوا استفاده می کند. تخصص ما شامل هیت سینک های مسی-آلومینیومی، اجزای اکسترود شده آلیاژ آلومینیوم، اجزای اتلاف حرارت ماشینکاری شده و اجزای اتلاف حرارت ریخته گری آلیاژی است.

نوآوری های تکنولوژیکی

ما به پیشرفت های متعددی در فناوری خنک کننده طبیعی دست یافته ایم، از جمله:

- فناوری پره های شیاردار با چگالی بالا برای پره های فوق العاده نازک و گام ریز

- جوشکاری اصطکاکی پیشرفته برای اتلاف حرارت ساختار فوق العاده گسترده

- عملکرد اتلاف حرارت برتر با 100٪ استفاده از هدایت حرارتی پروفیل

نوآوری های ما باعث بهبود قابل توجهی در راندمان اتلاف حرارت برای کاربردهایی از جمله سیستم های UPS، منبع تغذیه، اینورترها، ذخیره انرژی خورشیدی، باتری های برق و موتورهای حمل و نقل ریلی شده است.

نمودار توزیع دما از هیت سینک در جهت افقی

نمودار توزیع دما در بخش مرکزی مدل

کاربردهای صنعتی

تولید پیشرفته

- تولید نیمه هادی و تراشه:راه حل های حرارتی بسته بندی پیشرفته برای انباشت سه بعدی

- محاسبات هوش مصنوعی/مراکز داده:خنک کننده با چگالی شار حرارتی بالا برای بهینه سازی توان محاسباتی

- هوافضا:مدیریت حرارتی برای محیط های دمایی شدید و خلاء

کاربردهای زندگی روزمره

- دستگاه های دیجیتال:کامپیوتر، تلفن همراه، کنسول های بازی

- دستگاه های ارتباطی:سیستم های انتقال داده با سرعت بالا

- لوازم خانگی:کمپرسورها و واحدهای کندانسور

- دستگاه های روشنایی:مدیریت حرارتی مهره لامپ LED

- وسایل نقلیه انرژی نو:سیستم های خنک کننده مایع پیشرفته

قابلیت های تولید

کارگاه قالب پیشرفته ما دارای 22 دستگاه EDM از جمله دستگاه های MAKINO mirror EDM و دستگاه های برش سیم Seibu/Sodick از ژاپن، به علاوه تجهیزات سنگ زنی، فرز و تراشکاری جامع است.

مشخصات تجهیزات

- اندازه میز: 500×350 میلی متر

- سرعت عبور سریع: 5000 میلی متر در دقیقه

- حداکثر وزن قطعه کار: 500 کیلوگرم

- حداکثر وزن الکترود: 50 کیلوگرم

مهندسی دقیق

با استفاده از فناوری های SuperSpark4 و IES برای منبع تغذیه تطبیقی پیشرفته و کنترل پرش، اطمینان از پرداخت سطح عالی و کیفیت متالورژیکی.

کاربردهای محصول

تضمین کیفیت

تجهیزات تست جامع قابلیت اطمینان محصول را تضمین می کند:

- دستگاه اندازه گیری مختصات

- ابزار پروژکتور

- دستگاه های تست فشار قوی آب (2 واحد)

- دستگاه های تست مقاومت حرارتی (4 واحد)

- دستگاه های تست نشت مایع (2 واحد)

تعهد خدمات مشتری

- پاسخ سریع به تمام سوالات

- قیمت رقابتی با کیفیت تضمین شده

- برنامه ریزی تولید کارآمد

- راه حل های حمل و نقل بهینه

- پشتیبانی فنی جامع

سوالات متداول

آیا شما یک شرکت بازرگانی هستید یا تولید کننده؟

ما یک تولید کننده حرفه ای هیت سینک و صفحات خنک کننده آب با تجربه گسترده و یک تیم فنی قوی هستیم که دارای تولید خودکار و مکانیزه است.

آیا قبلاً کالا صادر کرده اید و به کدام مناطق؟

60٪ از کل تولید ما به ژاپن، هند، بریتانیا، کانادا، ایالات متحده آمریکا و برزیل صادر می شود.

چند کارمند دارید؟

تقریباً 100 کارمند در بخش های فروش، خرید، مهندسی، تضمین کیفیت، انبار و تولید.

آیا می توانید نمونه هایی را در صورت موافقت با طرح ارائه دهید؟

بله، ما نمونه هایی را برای تأیید قبل از تولید انبوه، همراه با نقشه های فنی در صورت نیاز ارائه می دهیم.

از چه روش های بسته بندی استفاده می کنید؟

بسته بندی سفارشی با کارتن های معمولی و پارچه ضد نفوذ یا کارتن های چوبی برای محافظت بهینه در حین حمل و نقل.

آیا برای مشکلات محصول پشتیبانی فنی ارائه می دهید؟

تمام محصولات قبل از حمل و نقل به طور کامل بازرسی می شوند. برای هر مشکلی، ما راه حل های فنی فوری ارائه می دهیم.

می خواهید اطلاعات بیشتری در مورد این محصول بدانید